4th of July Sale - 20% Off Site Wide!

Sale ends 6-Jul-25 11:59pm CT

*Discount applied automatically at checkout

**Sale excludes IK-100 Series Rifles

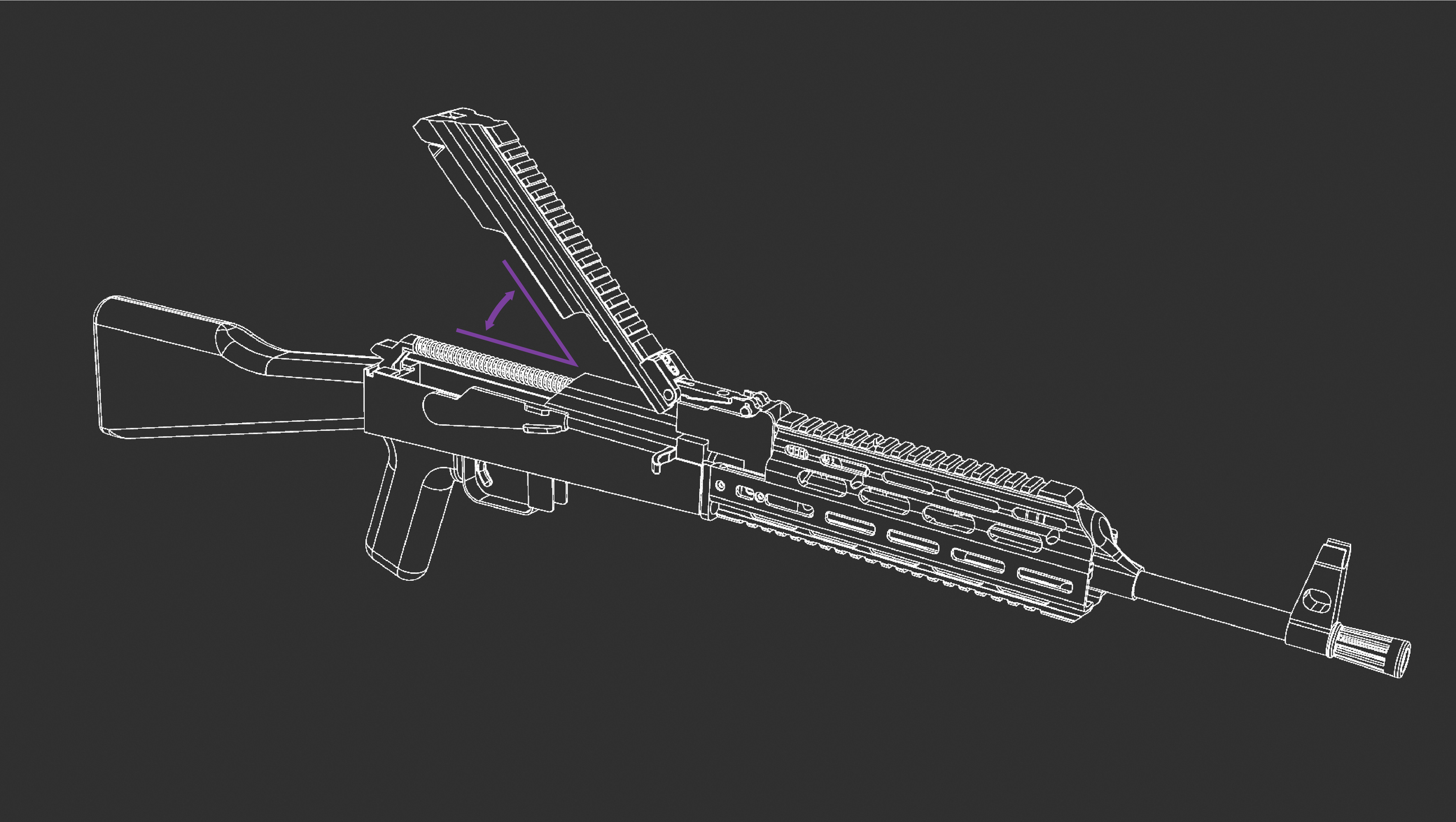

How Does it Work: Dog Leg™ Rail

“Does it hold zero?”. We get this question a lot. What we’ve found over the years is when people ask “does it hold zero?”, what they really want to know is “how does it hold zero?”. With no moving parts the Dog Leg™ rail is deceptively simple in design while containing many advanced design features. In this article we’re going to examine those features that ensure a reliable and repeatable return to zero. We'll also cover the additional features that solve the shortcomings of old school side mounts and make TWS the premier AK optic mount solution.

How does it hold zero?

To obtain a consistent and repeatable zero we must achieve two distinct goals.

1. The mount must be restrained in three axes of movement, vertical, lateral, and rotational.

2. The mount must return to the exact same place after each opening or removal.

The TWS Dog Leg™ rails use a 3-pronged approach to ensure the top cover returns to a consistent and repeatable zero. Those three prongs are the quick release hinge fork with the adjustable hinge base it mounts to, the flexural spring panel, and the cam lock release button. Let's examine each in more detail.

1 - Hinging assembly

At the front of the Dog Leg™ rail, you’ll find the hinging assembly, comprised of the quick release hinge fork and the adjustable hinge base that it attaches to.

The front hinging assembly serves multiple functions.

1. Provide a solid hinge point from which to open the cover during maintenance.

2. Provide for user adjustability to tailor fitment to the user’s rifle and use-case.

3. Provide a quick release functionality to aid in maintenance.

To ensure a repeatable return to zero and to control the friction in the hinging mechanism the hinge base is width adjustable. The width of the hinge can be increased by inserting a flat blade screwdriver (or similar wedge tool) into the slot at the back of the hinge base and lightly tapping with a hammer or mallet. The hinge can be widened to remove any side-to-side play and increase hinge friction.

To reduce hinge friction a set of locking pliers can be used to lightly clamp down on the sides of the hinge base, narrowing the hinge base. This adjustability allows the end user to tailor the friction for their desired use case. For example, a marksman, needing superior accuracy, would want to increase friction and remove side to side hinge play to ensure accurate engagements at distance. A machine gunner employing an RPK on the other hand might want a looser fit for ease of field stripping and maintenance.

The front hinging assembly is also responsible for constraining the motion of the front end of the cover. As we just discussed, the hinge base can be adjusted to remove any side-to-side play, but the hinging assembly also constrains vertical movement. This ensures a rock-solid mount that won’t move under fire, but still allows for field stripping and maintenance by means of the hinging assembly. The other features and adjustments of the hinging assembly will be touched upon later in this article.

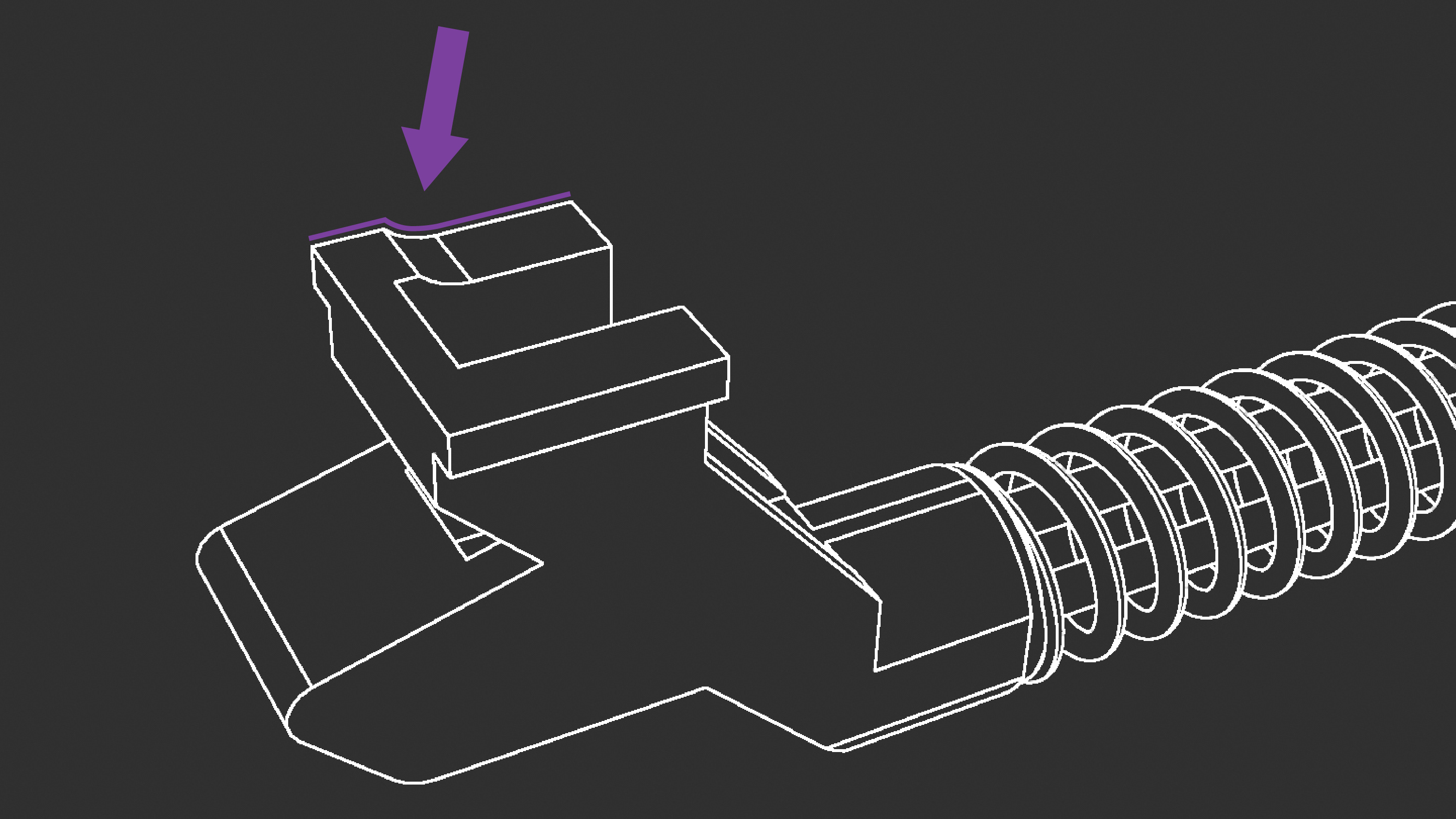

2 - Flexural Spring Panel

Moving back on the cover, on the right-hand side you’ll notice an angled slit cut into the cover. The triangular “tail” this slit forms is bent inward slightly.

This inward bent tail causes an interference with the receiver, thereby flexing the side panel when the cover is closed. The flexing side panel puts consistent pressure on the receiver always pulling the cover from left to right until it makes contact with the receiver. The spring panel eliminates side to side play at the rear of the cover body and provides a consistent and repeatable datum from which a zero can be achieved. The tension on the receiver can be adjusted by increasing or decreasing the bend of the triangular tail. Similar to the previous example with the hinge fork, the tension can be adjusted to suit the intended use case of the weapon system. It should be noted that there should always be some tension on the receiver, as without tension the cover won’t hold zero. You can adjust for more or less tension, but never for zero tension. Care should be taken to not over bend the tail as too much bend can cause the tail to become brittle and break off, necessitating a replacement cover body. Subtle adjustments only.

3 - Release Button

The final prong to our 3-pronged approach is the cam lock release button. Our proprietary release button design replaces the original factory release button. The button is cut at a 15-degree angle below the thumb pad forming a cam surface. This cam surface interfaces with the bottom surface of the release button hole in the cover body and, much like a wedge door stop, clamps down the cover to the rear trunnion. The broad width of the cover body clamping down on the trunnion, the most solid part of a rifle, restrains the cover in the three axes previously discussed.

With each firing cycle the bolt carrier group cycles rearwards, compressing the recoil spring assembly. This in turn pushes rearwards on the release button forcing its cam surface to act on the cover body and clamp it tight against the receiver with every shot. This mechanism ensures that the cover is at its tightest during the most violent portion of recoil, eliminating any vertical play in the cover and squaring it up against the rear trunnion to eliminate any roll movements as well.

Additional Features and Benefits

The front hinging assembly, in conjunction with the spring panel and release button ensures a rock-solid attachment of the Dog Leg™ rail to its rifle allowing for an accurate zero. The adjustability of the hinge base, alongside the consistent datum provided by the spring panel and release button eliminating side to side and vertical play respectively, causing that zero to not only be accurate, but repeatable.

Dog Leg™ Shape

Scoped AK rifles require a very low mounted optic to obtain a proper cheek weld for consistent shooting. One only needs to consider the height of the standard iron sights to confirm this. The patented stepped design or “dog leg” profile, from which the Dog Leg™ rail gets its name, was incorporated into the design to lower the rail surface as much as possible, reducing the height over bore and, in some cases, permitting co-witnessing of optics with the factory front sight.

Form Factor

Form factor is an important part of any design, but especially so when the product has life or death implications. The form factor of the TWS Dog Leg™ rail is optimized to provide the greatest capability possible without adverse effects to the weapon.

By keeping the contours of the Dog Leg™ rail dust covers close to that of the original stamped steel dust cover, we’re able to provide users with generous rail space without disrupting the original profile of the AK platform. Unlike bulky side mounts, the slim design of the Dog Leg™ rail does not protrude in any direction, nor does it unbalance the rifle with large, asymmetric mounting structures. The slim design also does not snag on gear or the environment like side mounts can.

The slim design of the Dog Leg™ rail makes it compatible with folding stocks. Right and left side folding stocks, as well as under folding stocks are all compatible with the Dog Leg™ rail.

The generous rail space atop the Dog Leg™ rail (14-16 slots depending on model) gives users plenty of space to mix and match optics, magnifiers, iron sights and other devices. This affords users further flexibility to customize their rifle to their specific mission profile without compromising on performance.

The generous rail space also permits the mounting of a rear iron sight at the extreme rear of the receiver, nearly doubling the factory sight radius.

Due in part to its 6061-T6 aluminum construction, the Dog Leg™ rail achieves its performance with only a minimal increase in weight (approximately 1oz).

Hinge Fork

The hinge fork, in addition to being a critical element in holding zero as part of the hinging assembly, also has a number of its own features that aid in the overall function and usability of the Dog Leg™ rail

The hinge fork features a captive AR-15 takedown pin as it’s hinge pin. This allows the cover to be hinged open for maintenance, but also to be removed if needed.

The takedown pin also allows for the use of longer scopes that overhang the hinge mechanism. Normally if a scope overhangs the hinge on a dust cover type mount, the scope will collide with the gas tube or hand guard when trying to open the cover for maintenance. With the TWS Dog Leg™ rail this problem is resolved by the takedown pin. Simply pop the release button in the rear to alleviate some of the tension on the hinge and then use the takedown pin to remove the cover from the rifle. This eliminates the need to remove the scope from the cover or use a quick detach scope mount. In fact, due to the comparatively low cost of the Dog Leg™ rail (when compared to high end QD scope mounts) we’ve had some customers buy multiple covers for the same rifle, each one equipped with a different optic. Simply change out the cover by way of the takedown pin and you’ve completely changed optics. Because each optic is zeroed to the cover and rifle it’s mounted to, as long as you don’t mix and match covers between rifles, the optics will remain zeroed to the rifle they were originally zeroed on. If you want to move optics from one rifle to another, it’s just as fast, you’ll simply need to re-zero on the new rifle.

The hinge fork also has an adjustment slot for the screws which permit overall length adjustment of the Dog Leg™ rail. This adjustment takes into account manufacturing variance and differences in rifle design across source nations, ensuring a perfect fit on your specific rifle.

Release Button

The underside of the release button has a subtle step machined into it. This step is designed to accommodate the rear trunnion locking release button mechanism on Zastava (Yugo) rifles. This step does not adversely affect performance on rifles without the locking mechanism.

The rear face of the release button features a machined dimple, designed to aid in the removal of the cover under adverse conditions. The dimple permits the use of a pointed tool to aid in pressing the release button, should the button become stiff due to fouling or other factors.

Receiver Stiffness

The overall stiffness of the Dog Leg™ rail and its mounting mechanisms provide additional benefits to the rifle it’s mounted on. We often receive reports of rifles inexplicably “feeling better” when firing after installation of the Dog Leg™ rail, but users are often unsure as to exactly why or how the rifle feels better. This improved feeling goes back to the stiffness of the Dog Leg™ rail itself. Think about an empty shoe box for a moment. When the lid is removed from the shoe box, the box becomes quite flexible, easily bent or twisted in the hand. Now if you take the lid and securely place it on the shoe box, the box becomes substantially more rigid and difficult to bend or twist. A similar effect happens with the AK rifle. A normal AK with its stamped receiver and original stamped dust cover is a lot like the open shoe box. Because the original dust cover does not mount rigidly to the receiver, it imparts little if any stiffness. When the rifle is fired, the recoil impulse is translated from the barrel, through the receiver into the stock, and finally into the shooter’s shoulder. Newton’s third law tells us that for every action there is an equal and opposite reaction. This obviously manifests itself in the form of recoil. When the bullet is launched out of the barrel at high speed, the equal and opposite reaction is the recoil impulse that pushes the weapon back into the shooter’s shoulder, but there is a secondary, less obvious reaction. The barrel’s rifling imparts spin into the bullet, but the bullet resists this and, in turn, imparts an equal and opposite reaction into the rifle in the form of a subtle torque on the weapon. This torque is imperceptible to most people, but it’s still present and acts on the weapon. On a standard AK this torque twists and deforms the receiver along the barrel’s axis causing the weapon to feel “loose” or “squirrely”. When the Dog Leg™ rail gets mounted to the weapon it serves to stiffen the receiver, much like the shoe box with its lid attached. Notice that the Dog Leg™ rail cover body is substantially thicker and more rigid than the stamped AK receiver it is mounted to, further contributing to the added stiffness. This stiffness resists the twisting of the receiver during firing and serves to make the weapon feel more rigid and stable. This stiffness and the sensation of stability it provides is the source of AKs inexplicably “feeling better” after mounting a Dog Leg™ rail.

Think of “feeling better” in this way. If you’re playing some basketball just shooting hoops and your shoe laces come loose then you’re less effective. The moment your laces are tied your shoes “feel better” and now you can drive the game harder and be more aggressive with your target. Sure, it’s a subtle and intangible benefit, but it’s important and free, so let’s take it.

Texas Weapon Systems products are covered by U.S. and international patents.

#US8407925B2

#US10018445B2

#USD791899S1

#USD792547S1

#USD680186S1

Solar theme designed by epicShops